Advanced Fluorescent Fiber Optic Temperature Sensors

As a world-class manufacturer, FJINNO delivers the most reliable and precise temperature monitoring solution for critical assets in harsh electromagnetic and corrosive environments.

The Unmatched Advantages of FJINNO's Fluorescence-Based Sensors

Our fluorescence sensor technology isn't just an alternative; it's a fundamental upgrade over traditional and other optical sensing methods. Here’s why industry leaders choose FJINNO.

Complete EMI/RFI Immunity

Being made of non-conductive materials, our optical temperature sensor is completely transparent to electromagnetic and radio-frequency interference. This makes it the only reliable choice for high voltage switchgear condition monitoring and inside MRI machines.

Intrinsic Safety

There is no electricity at the point of measurement. This eliminates any risk of sparks or electrical discharge, making our sensors intrinsically safe for use in explosive or flammable environments like oil-filled optics transformers and chemical reactors.

High Accuracy & Stability

Our measurement is based on the immutable physical property of fluorescence decay time. This provides exceptional accuracy (±0.2°C) and long-term stability without any need for recalibration, ensuring reliable thermal monitoring for decades.

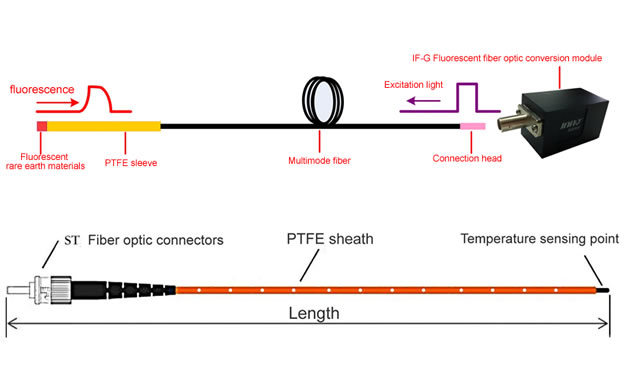

The Science of Light and Heat

Our system uses a proven principle called fluorescence decay. It's a simple, elegant, and incredibly robust method for temperature measurement.

Light Pulse Sent

Our fiber optic thermometer sends a short pulse of blue light down the fiber optic probe.

Fluorescence Activated

The light excites a tiny amount of phosphor material at the sensor tip, causing it to fluoresce (emit red light).

Decay Time Measured

The instrument precisely measures the time it takes for this fluorescence to fade. This decay time is directly and repeatably related to the temperature at the sensor tip.

Technology Comparison

See how our optical fiber temperature sensor technology stacks up against conventional methods. It's not just a different device; it's a superior device that is responsive to ambient temperature conditions in challenging settings.

| Feature | Fluorescent Fiber Optic | Thermocouple | RTD / Resistance Thermometer | Infrared Pyrometer |

|---|---|---|---|---|

| EMI/RFI Immunity | ✓ | ✗ | ✗ | ✓ |

| Intrinsic Safety (High Voltage) | ✓ | ✗ | ✗ | ✓ |

| Needs Recalibration | ✗ | ✓ | ✓ | ✓ |

| Accuracy | Very High | Medium | High | Low-Medium |

| Direct Point Contact | ✓ | ✓ | ✓ | ✗ |

| Ideal for Hot Spot Monitoring | The Best | Poor | Poor | Fair |

Engineered for the Most Demanding Applications

Our fiber optic sensor systems are trusted by leaders in industries where temperature is a critical parameter and conventional sensors are not an option. We are the premier supplier for these sectors.

Power Transformers

The definitive solution for direct transformer hot spot monitoring. Our winding sensor is placed directly on the windings for true transformer winding temperature measurement, essential for any condition monitoring of transformer program.

MV/HV Switchgear

Enhance safety with our breaker monitoring system. Monitor busbars, joints, and critical switchgear components in real-time. A must-have for modernizing any electrical switchgear diagram.

Generators & Motors

Ideal for rotating equipment condition monitoring. Monitor stator windings in hydro generators and perform wind turbine condition monitoring without risk from high magnetic fields.

Medical MRI & RF

The gold standard for patient and equipment monitoring inside MRI bores. Our mri monitor provides accurate mr temperature readings without creating artifacts or safety risks. Essential for gb3 application.

Semiconductor Processing

Achieve precise wafer temperature measurement during plasma etch and deposition. Our wafer sensor is immune to RF fields, enabling better semiconductor process control and yield.

Industrial Microwave & RF

When sensing microwave energy, traditional sensors fail. Our fiber optic transducer provides accurate temperature data for industrial cooking, drying, and material curing processes.

Our Product Ecosystem

We provide a complete, end-to-end customized system, from the sensor tip to your control room display. Every component is manufactured in our factory to the highest standards.

Fluorescent Fiber Optic Temperature Sensor

Our flagship sensor fiber optik, available in a wide range of probe designs for different applications, including our rugged transformer winding temperature sensor.

Fiber Optic Monitoring Device

Multi-channel signal conditioners that serve as the central transformer monitor or system controller. They provide data output via Modbus, IEC 61850, and analog signals.

Control & Analysis Software

Powerful software for real-time monitoring, data logging, and trend analysis. The core of any effective transformer monitoring system or substation monitoring platform.

Your Global Manufacturing Partner

FJINNO is a vertically integrated manufacture. We offer flexible partnership models for OEMs, system integrators, and large-scale projects. We are a trusted exporter and dealer worldwide.

OEM / ODM Solutions

Integrate our proven technology directly into your products. We provide full OEM / ODM support, from engineering to branding. We are the best private label partner.

Wholesale & Bulk Supply

We support our global distributor network with competitive pricing for wholesale and bulk orders, ensuring your market success and profitability.

Custom Engineering

Have a unique challenge? Our R&D team can develop a fully custom sensor solution, including high-temperature optical fiber solutions and unique probe designs.

Ready to Upgrade to The Best Temperature Monitoring Solution?

Contact our expert engineering team today to discuss your specific application, request technical datasheets, or get a quote for your project. Let's build a safer, more reliable future together.

Request a Quote